After taking over at Paty, Inc., Derrick and Caren Veillon revamped the storied infant brand by paying homage to its Peruvian-born, American-made roots. Here, Derrick reveals why their labor of love will reap big dividends in 2014. By Audrey Goodson Kingo Ruth Abugattas (right) helped found Paty, Inc. in 1955 and paved the way for […]

After taking over at Paty, Inc., Derrick and Caren Veillon revamped the storied infant brand by paying homage to its Peruvian-born, American-made roots. Here, Derrick reveals why their labor of love will reap big dividends in 2014.

By Audrey Goodson Kingo

Ruth Abugattas (right) helped found Paty, Inc. in 1955 and paved the way for the brand’s current owners, Derrick and Caren Veillon.

Not many children’s companies can say American history is woven into the very fabric of their brand—literally.

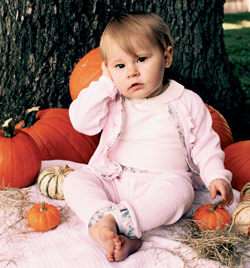

While more and more companies may be jumping on the Made-in-the-U.S.A. bandwagon, most still look overseas when it comes to sourcing their fabrics. Not so for Paty, Inc. The Houston-based industry stalwart has supported the American textile industry for more than 40 years, sourcing the thread that makes up its signature knit from cotton mills in North Carolina. But it’s not only the thread and fabric that make every Paty, Inc. piece undeniably an American product. It’s also the story of the brand itself, a tale that embodies the very meaning of the American dream.

Like many an American story, it begins in another country, in 1955, when two sisters decided to launch a children’s company in their hometown of Lima, Peru. As teenagers, Ruth and Faride Abugattas used hand-powered looms in their home to make their own clothes. Their designs became so popular that by the time the sisters were in their 20s, they were manufacturing women’s clothing for much of the South American market. But with the birth of their niece, Paty, the two shifted gears and began making children’s clothing—and Paty, Inc. was born.

When the political situation became unstable in their beloved country, the sisters looked to America for new opportunities, and moved the company to Houston in 1970. With new knitting machines from Germany, sewing machines from Italy, a 4,500-square-foot facility and a team of four, the sisters began producing what would become one of the bestselling infant apparel brands in the U.S.

Of course, it wasn’t easy at first—especially for two women from another country in the height of the Mad Men-era of business. “Being a Latin woman was a big challenge because even though you learn English in school you never practice it, and you have an accent,” says Ruth Abugattas, who served as vice president at Paty, Inc. until the sisters decided to sell the company in 2010. “At that time, there weren’t many Latin women in the United States, particularly in Houston. When we called people, they would ask for a Mr. Abugattas, and when we would say we don’t have a Mr. Abugattas, they would hang up the phone on us.”

“>

“>

Through all the setbacks and successes, the sisters persevered, and built the brand into a nationwide presence, never once wavering on their commitment to manufacture in Houston, despite the difficulties of sourcing affordably-priced thread and machine components in a dwindling American textile market. Ruth largely chalks their success up to Faride, who served as the company’s president and passed away in 2011. “My sister was very intelligent and clever and she pushed us very hard,” Ruth describes. “Sometimes you don’t like it, but you end up being very grateful.”

Paty’s commitment to American manufacturing and rich, distinctive history is exactly why Derrick Veillon and his wife Caren gravitated toward the company when it became available in 2010. That, and the fact that the pair had a vested interest in children’s clothing, as the proud new parents of a 7-month-old girl. “After we met Ruth, we went down to the location and saw what Paty produces, and we fell in love with the clothes and the story of the company,” Veillon describes. “It was like walking into a big toy store. It was just a perfect fit for us.”

It was also a perfect fit for Ruth, who was looking forward to enjoying her hard-earned retirement. Now, Derrick serves as president while Caren operates as the vice president of design and merchandising. With 10 years of experience in the gift industry, the two certainly weren’t novices in the wholesale industry, but decoding the children’s apparel market and mastering the ups and downs of domestic production, on the other hand, required a bit of a learning curve.

While the Veillons could have rested on Ruth’s laurels and kept the respected brand chugging along at status quo, instead they decided to dive in full-force and ramp up its operations to fit a 21st-century marketplace, all the while staying true to its Peruvian-born, American-made bona fides. That meant making an array of savvy changes, including last year’s launch of a Peruvian-produced pima cotton collection, called Beginnings, that pays homage to Paty’s roots. The couple also created a new website for the company, updated the brand’s accounting system, revamped the look of its label, hired a dozen new employees and recently announced the addition of four new reps across the U.S.

At times it’s been a whirlwind, but as Derrick points out, it’s worth it for the opportunity to boost the brand back to its former prominence, when parents across the country could pick up a Paty, Inc. one-piece for their little ones. And fortunately, the couple has a rock solid mentor in Ruth, who still stops by the office to provide advice. “Without her guidance in the beginning, it would have been really tough, especially without her showing us the basic function and flow of the production process,” Derrick notes. “After 40 years, it’s become second nature to her. She had so much to share, and it was a joy to learn from her.”

That sense of respect is mutual, Ruth adds, calling the couple “enthusiastic.” Listening to Derrick’s impressive list of plans for Paty, Inc., it’s easy to see why. And with a brand story so well suited to fit the needs of the current market, as parents increasingly seek authenticity in their purchases, it’s also easy to see why the company is perfectly poised to prosper as it heads into its 60th anniversary next year.

How did your previous experience in the gift industry help you take over the reigns at Paty?

Our previous firm was positioned similarly in the supply chain, and we had been going to the market centers for 10 years, working with many of the same customers we have now. So going from gift to apparel was an easy transition to make. Besides the operational similarities, we were also previously part of a team that took the firm from being in a reorganization status to profitability, eventually becoming a leader in the gift industry. We rode the roller coaster from the bottom to the top, so to speak. The experience we gained during that time was crucial, both in the early days at Paty and even today. The most important thing we took away from it is to believe in what we produce. We take a lot of pride in knowing that Paty and Beginnings pieces will very likely become part of the first memories that families make with their children, and that means a lot to us and to the people who work for us, too. They know they’re not making widgets to be cranked out, used and disposed of. They’re making pieces that become part of families’ lives.

What were the biggest challenges in the beginning?

There were two major challenges. The biggest was that Ruth kept an accurate but antiquated system of books. Her system dated back to the ‘70s, using general ledgers, pencil, paper and calculators. We immediately had to update it and automate it with an accounting system, so we could keep up with all the data from sales and customer contact information. The next big challenge was to make Paty more accessible to retailers by giving the company an online presence, which at that point it didn’t have. We launched the first website in December of 2010, and now it actually accounts for a pretty healthy percentage of sales.

UPCLOSE with Derrick Veillon

What are you reading right now?

I just finished the book Killing Kennedy by Bill O’Reilly. I enjoy history and believe that we can learn so much by studying the past. I’m also re-reading Good to Great by Jim Collins. It reminds me to shrug off complacency and pursue greatness in everything we do both personally, and as a company.

What superpower would you love to have?

I would love to be able to fly so I could avoid the Houston traffic and fly into work.

What’s your favorite way to spend a free afternoon?

Ideally, I’d love to be in the backyard bouncing on the trampoline or playing kickball with my family. My wife and I have a 7-year-old little boy and a 3-year-old little girl. Everybody told us when these guys were small they were going to grow up too fast, and we’re seeing that now. We try to live a life with a no-regrets attitude. We just want to make as many memories with them as we can.

What three items could you never live without?

The things I truly value in life are my faith, my family and the ability to work hard to earn a living (in that order). At the end of the day, everything else is just fluff.

What’s the best piece of advice Ruth gave you?

Ruth doesn’t like to veer too far off the designs that Paty is known for, so her biggest piece of advice was to keep things consistent and not make any drastic changes. A lot of our bestsellers are based on designs that she and her sister created back when the company first started. No matter how many other brands offer similar styles, she said, don’t try to recreate yourself. So we’re sticking with what works, per her advice.

How do you decide what styles are working?

Every three months we evaluate the performance of every single item, and we keep the pieces that are still in demand. We often know what pieces are going to sell; it’s the pieces Ruth told us would sell, the pieces she’s been carrying for years, our everyday styles that are available year-round. I think those are a staple in the infant apparel industry and very likely will not change in the future. We may tweak those pieces and offer some different colors, but the styles themselves are so popular and practical that we leave them alone. We have other seasonal pieces that we shake up a little bit, with different colors, materials and fabrics. Using a mix of feedback from our customers and market trends, we try to develop pieces that our customers will want. My wife does a lot of the design, and during the last couple of years she’s noticed an increased demand for new pieces. People love the staple items, but they also want to see what’s new, what else they can show their customers. So after listening to our customers and analyzing the trends, we try to provide a fresh spin on our own classic styles.

So what makes Paty stand out from brands that offer a similar look?

Besides the fact that we’re made in America, which counts for a lot, we’re also able to control the entire manufacturing process, which puts us right on top of quality and right on top of making any immediate changes. If we get feedback from a customer that a pattern needs to be adjusted on a certain piece, we don’t have to discount a whole batch of product. We can make a change on the fly and keep the quality at first-run every time. We even make our fabric here on knitting machines, so we have control of the quality of the fabric, too.

Making your own fabric is so rare these days!

We consider ourselves pretty unique in that we actually create the fabric onsite. We buy the yarn, a cotton/polyester blend, out of a spinning mill in North Carolina. Then we put cones of yarn on the two knitting machines, and the machines run it through the process and out comes the fabric! That’s our signature Paty knit. From there we pass it on to the cutting table and it goes through a standard production process. That’s why our slogan for a while was, ‘We start with the yarn,’ because we really do. We purchase fabric like seersucker and other wovens for some of the pieces we make, but the bulk of our volume is made from fabric we produce.

That’s a fantastic brand story.

People love to hear the story. There’s such a rich history with Paty that goes back generations. And our retailers love to tell the story. When shoppers come into their stores, the first thing they do when somebody asks about Paty is say it’s made in Texas and started in Peru—and I think that means a lot to their customers. The designs themselves are traditional, they’re solid and they’re tried and true. We’re not protected against other companies doing the same, so I think we help to differentiate ourselves on the quality, on the story and also by providing excellent customer service to our retailers.

It must help that more consumers are looking for Made-in-the-U.S.A. products.

We have a lot of store owners who tell us we’re their No. 1 selling brand, and not just because we’re made in the U.S.A., but also because we’re able to manage our pricing. We’re able to compete with the importing companies with a price point that’s consistent with the rest of the market, whereas many U.S.-made products tend to be 20 to 30 percent higher. One of the biggest challenges of manufacturing here is balancing the fact that you want to source most of your components in the U.S., but you also want to have a competitive price point. That’s why we really work hard to make sure our components are priced well, so that we can pass those savings down to the customer and give them a Made-in-the-U.S.A. product at a good price point, and not one or the other.

How difficult is it to keep those production costs down?

It’s a big challenge. A couple years ago we lost one of our main components when our thread supplier went out of business. We had to source another supplier and make sure that the color, tensile strength and price was right, and that it worked well in our machines. That happens a few times a year, with pretty important components. We have to make sure we can replace them with equally usable components within the same price range, so we don’t have to push the price up just because our component price went up.

It’s even becoming difficult to keep production prices down on imports, too, right?

Our Beginnings brand is imported from Peru, and has nearly the same price point as Paty. We work hard to make sure it doesn’t get priced out of the market, but in a country like Peru, that’s recently been inundated with American demand, it’s not easy to do. By definition, price has to go up when demand goes up, and all those costs sometimes get passed on to us, which can be tricky to manage. Unless there is a drastic decrease in demand for imported goods, soon the consumer may be able to get American-made products at a better price than some imported pieces.

All of Paty, Inc.’s designs are manufactured at its Houston headquarters.

How does the Beginnings line compete with other Peruvian brands on the market?

When we launched the Beginnings collection in July of last year, we approached it with a business model that wouldn’t put us head to head with other Peruvian importers. We wanted to focus more on design and stay true to our own classic and original styles. In order to balance price and design, we research the industry to make sure we remain competitive, while focusing on innovation. With that said, having a line manufactured in the United States helps us receive immediate feedback from our customers, allowing us to learn their tastes and styles. That feedback goes into the design process for new pieces for Beginnings and often results in something completely new and something the market demands.

Do the retailers who buy Paty also buy Beginnings, or is it a different customer?

It’s the same retailer, but it’s a different niche. Most retailers will have room for Paty in their store, but they will also have room for a Peruvian pima cotton import with a little bit of a different look. So the Beginnings line isn’t really competing with Paty dollars, and a lot of the time it’s the same customer who purchases both lines. It’s a complementary line, with a comparable price point, and that’s how it was designed by intent.

So how would you rate 2013 for Paty?

Last year was excellent. We spent a lot of it planning for 2014, and we’re hoping to reap the fruits of all that planning this year. In January of this year, we announced the addition of four new reps across the country, so we can put Paty back into the markets where we were once prevalent, in the West Coast, Midwest, Northeast and Mid-Atlantic areas. That’s going to be a big push for us. We’re also re-working the Dallas area and how we manage and relate to customers. We feel that putting reps in place and managing the shows a little differently will allow us to position ourselves closer to the retailer and solicit feedback in a better way. We also made some investments in some really talented people in design, management and sales at the end of last year, so we’re really looking forward to jumping into 2014, and rolling out some tweaks for production to keep up with demand.

Do you think Paty’s traditional designs will resonate outside the South?

Absolutely. Our traditional pieces have always sold well, and they still sell well in the West Coast and other territories, but we’re also tweaking the line a little bit, per what the demand is in a particular area. If we need to tweak a style a little bit, we’ll make that change, so it fits the needs and the taste of that market. And because we manufacture here, we have the flexibility to make that change instantly and have it in our reps’ hands within a couple of days.

What’s been your favorite part of the job so far?

My wife and I are just blown away by the potential that Paty has and the kindness of the customers we get to work with, and their willingness to share with us as we create new pieces. They really make it all worth it. Sales and profits can be through the roof, but if at the end of the day you don’t enjoy who you work with, both outside the office and internally, it’s all for naught. We love what we do, and we’re happy we can share it with people.

Leave a Comment: